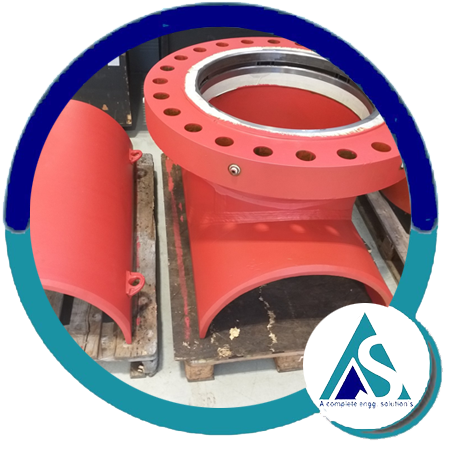

Split Tee Fittings

Aditya Steel Engg. Co is split tee weld Fitting is the latest in the series of value-added product, high performance, innovative split tee fittings, tee fittings, pipeline split tee fittings, high, pressure split tee fittings, pipeline connections, welded split tee, bolted split tee, clamped split tee, split tee connectors, tee junctions split tee fittings, oil and gas , split tee fittings, chemical processing split tee fittings, power generation split tee fittings, water treatment split tee fittings, pipeline accessories split tee fittings products from Total Piping Solutions.

Split Tee Fittings are a type of pipeline fitting used to connect two or more pipes together in a tee configuration. They are called “split” because they are designed to be installed on an existing pipeline without having to shut down the flow of fluid.

Split Tee Fittings offer several advantages in pipeline systems, including:

1. Reduced Downtime: Split Tee Fittings can be installed without shutting down the pipeline, reducing downtime and increasing productivity.

2. Increased Safety: Split Tee Fittings eliminate the need for hot tapping, reducing the risk of accidents and injuries.

3. Improved Flow: Split Tee Fittings provide a smooth, uninterrupted flow path, reducing turbulence and increasing flow rates.

4. Enhanced Reliability: Split Tee Fittings are designed to withstand harsh environments and extreme temperatures, ensuring reliable performance.

Design Considerations for Split Tee Fittings

When designing Split Tee Fittings, several factors must be considered, including:

1. Pipe Size and Material: The fitting must be compatible with the pipe size and material.

2. Pressure and Temperature: The fitting must be designed to withstand the maximum pressure and temperature of the pipeline.

3. Flow Rates and Velocities: The fitting must be designed to accommodate the expected flow rates and velocities.

4. Corrosion and Erosion: The fitting must be designed to resist corrosion and erosion.

Installation Best Practices for Split Tee Fittings

To ensure safe and reliable installation of Split Tee Fittings, follow these best practices:

1. Prepare the Pipeline: Ensure the pipeline is clean, dry, and free of debris.

2. Measure and Mark the Pipe: Measure and mark the pipe to ensure accurate fitting placement.

3. Install the Fitting: Install the fitting according to the manufacturer’s instructions.

4. Test the Fitting: Test the fitting to ensure it is leak-free and functioning properly.

Common Applications for Split Tee Fittings

Split Tee Fittings are commonly used in various industries, including:

1. Oil and Gas: Split Tee Fittings are used in oil and gas pipelines to connect laterals, inject chemicals, and monitor flow rates.

2. Chemical Processing: Split Tee Fittings are used in chemical processing plants to connect pipelines, inject chemicals, and monitor flow rates.

3. Power Generation: Split Tee Fittings are used in power plants to connect pipelines, inject chemicals, and monitor flow rates.

4. Water Treatment: Split Tee Fittings are used in water treatment plants to connect pipelines, inject chemicals, and monitor flow rates.

Split Tee Fittings Characteristics:

1. Split design: Allows for installation on an existing pipeline without shutdown.

2. Tee configuration: Connects two or more pipes together.

3. High-pressure rating: Suitable for high-pressure applications.

4. Durable construction: Made from high-strength materials to withstand harsh environments.

Types of Split Tee Fittings:

1. Welded Split Tee: Welded to the pipeline using a specialized welding process.

2. Bolted Split Tee: Secured to the pipeline using bolts and nuts.

3. Clamped Split Tee: Held in place using a clamping mechanism.

Split Tee Fittings Applications:

1. Oil and gas pipelines: Used for connecting pipelines in oil and gas applications.

2. Chemical processing: Used in chemical processing plants to connect pipelines.

3. Power generation: Used in power plants to connect pipelines.

4. Water treatment: Used in water treatment plants to connect pipelines.

Split Tee Fittings Benefits:

1. Minimizes downtime: Allows for installation without shutting down the pipeline.

2. Cost-effective: Reduces the need for expensive shutdowns and restarts.

3. Increases safety: Reduces the risk of accidents and injuries associated with shutdowns.

Here are some common specifications for Split Tee Fittings:

General Specifications:

1. Size Range: 2-48 inches (50-1200 mm)

2. Pressure Rating: Up to 10,000 psi (689 bar)

3. Temperature Range: -20°C to 200°C (-4°F to 392°F)

4. Material: Carbon steel, stainless steel, alloy steel

Dimensional Specifications:

1. Tee Body Diameter: 2-48 inches (50-1200 mm)

2. Branch Diameter: 1-12 inches (25-305 mm)

3. Length: 6-60 inches (152-1524 mm)

Material Specifications:

1. Carbon Steel: ASTM A105, A350 LF2

2. Stainless Steel: ASTM A182 F304, F316

3. Alloy Steel: ASTM A182 F11, F22

Surface Finish Specifications:

1. Internal Coating: Epoxy, polyurethane, or ceramic

2. External Coating: Paint, varnish, or hot-dip galvanizing

Inspection and Testing Specifications:

1. Visual Inspection: ASME B31.4

2. Pressure Testing: ASME B31.4

3. Leak Testing: ASME B31.4

Certification and Compliance Specifications:

1. API 6D: Specification for Pipeline Valves

2. ASME B31.4: Pipeline Transportation Systems for Liquid Hydrocarbons and Other Liquids

3. ISO 14313: Pipeline Transportation Systems

Other Specifications:

1. NACE MR0175: Material Requirements for Sour Service

2. PED 2014/68/EU: Pressure Equipment Directive

Here are some reasons why Split Tee Fittings are used:

1. Easy Installation: Split Tee Fittings can be installed without shutting down the pipeline, reducing downtime and increasing productivity.

1. Reduced Risk: Split Tee Fittings eliminate the need for hot tapping, reducing the risk of accidents and injuries.

1. Increased Safety: Split Tee Fittings provide a safe and reliable way to connect pipelines, reducing the risk of leaks and spills.

1. Improved Flow: Split Tee Fittings provide a smooth, uninterrupted flow path, reducing turbulence and increasing flow rates.

1. Enhanced Reliability: Split Tee Fittings are designed to withstand harsh environments and extreme temperatures, ensuring reliable performance.

1. Cost-Effective: Split Tee Fittings can be more cost-effective than traditional tee fittings, especially in situations where shutdowns are not feasible.

1. Flexibility: Split Tee Fittings can be used in a variety of applications, including oil and gas, chemical processing, power generation, and water treatment.

1. Reduced Maintenance: Split Tee Fittings can reduce maintenance costs by providing a reliable and leak-free connection.

1. Increased Efficiency: Split Tee Fittings can increase efficiency by allowing for easier installation and maintenance of pipeline connections.

1. Compliance: Split Tee Fittings can help meet regulatory requirements by providing a safe and reliable way to connect pipelines.

Manufacturer and suppliers of split tee fittings, Manufacturer and suppliers of tee fittings, Manufacturer and suppliers of pipeline split tee fittings, Manufacturer and suppliers of high, Manufacturer and suppliers of pressure split tee fittings, Manufacturer and suppliers of pipeline connections, Manufacturer and suppliers of welded split tee, Manufacturer and suppliers of bolted split tee, Manufacturer and suppliers of clamped split tee, Manufacturer and suppliers of split tee connectors, Manufacturer and suppliers of tee junctions split tee fittings, Manufacturer and suppliers of oil and gas split tee fittings, Manufacturer and suppliers of chemical processing split tee fittings, Manufacturer and suppliers of power generation split tee fittings, Manufacturer and suppliers of water treatment split tee fittings, Manufacturer and suppliers of pipeline accessories split tee fittings

We export and Supply to :

- ASIA – India, Japan, Thailand, Singapore, Sri lanka, Bangladesh, South Korea, Indonesia, Philippines, Vietnam, Kazakhstan, Azerbaijan, Turkmenistan.

- Middle East – Kuwait, Dubai, Saudi Arabia, Qatar, Oman, Bahrain, Jordan, Turkey, Iraq, Yemen, Syria, Azerbaijan, United Arab Emirates, Israel.

- Western Europe – Germany, France, Netherlands, Belgium, Austria, Switzerland, Luxembourg, Monaco, Liechtenstein

- Eastern Europe – Russia, Ukraine, Poland, Romania, Czechia, Hungary, Belarus, Bulgaria, Slovakia, Moldova

- Northern Europe – United Kingdom, Sweden, Denmark, Finland, Norway, Ireland, Lithuania, Latvia, Estonia, Iceland, Isle of Man, Faeroe Islands

- Southern Europe – Italy, Spain, Greece, Portugal, Serbia, Croatia, Bosnia and Herzegovina, Albania, North Macedonia, Slovenia, Montenegro, Malta, Andorra, Gibraltar, San Marino, Holy See

- South America – Argentina, Chile, Brazil, Colombia, Paraguay

- Western Africa – Nigeria, Ghana, Côte dIvoire, Niger, Burkina Faso, Mali, Senegal, Guinea, Benin, Togo, Sierra Leone, Liberia, Mauritania, Gambia, Guinea-Bissau, Cabo Verde, Saint Helena

- Northern Africa – Egypt, Sudan, Algeria, Morocco, Tunisia, Libya, Western Sahara

- Southern Africa – South Africa, Namibia, Botswana, Lesotho, Swaziland

- Eastern Africa – Ethiopia, Tanzania, Kenya, Uganda, Mozambique, Madagascar, Malawi, Zambia, Zimbabwe, South Sudan, Rwanda, Burundi, Somalia, Eritrea, Mauritius, Djibouti, Réunion, Comoros, Mayotte, Seychelles