Aditya Steel Engg. Co. is fully furnised for fabrication and manufacturing in the product of Leak Repair Clamps which id applicable for emergency pipe leak repair work.

Repairing Pin-Hole Leaks clmps For the purpose of repairing holes or faults up to 12 millimeters in oil and gas processing facilities, clamps have been created. Clamps are offered in conventional sizes ranging from 2″ to 48″ and for pressures up to 153 Bar.

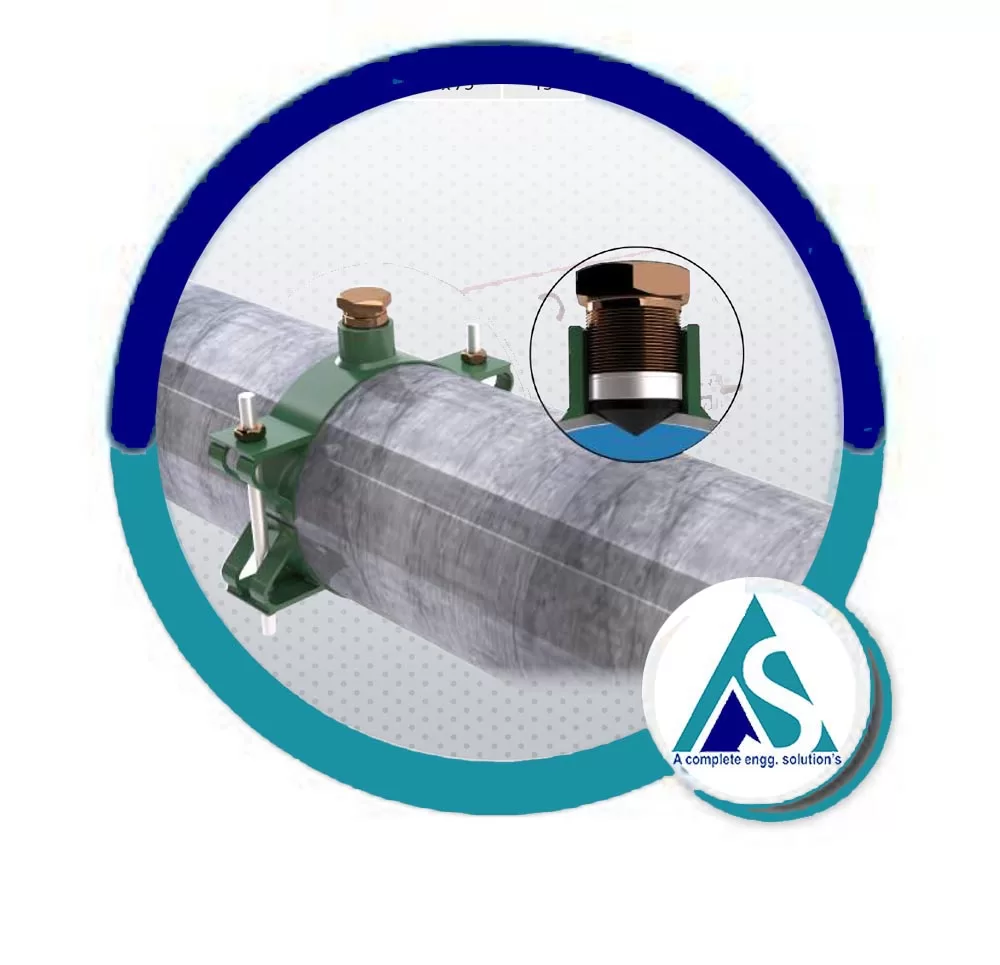

Pin-Hole Leak Repair Clamps.

For the purpose of repairing process pipelines in oil and gas processing facilities, pin-hole leak clamps were developed.

The piping and system functionality to which they are fitted can be installed with little interruption. Pin-Hole Leak Clamps are made to be easily installed and offer a quick and flexible fix for specific leak locations.

Manufacturers of Pipeline pin-hole pin-hole Repair Clampss, Manufacturers of Mechanical Couplings, Manufacturers of 2″ to 48″ MS Split Sleeve pin-hole Repair Clamps, Manufacturers of Style 360 Full Circle pin-hole Repair Clamps, Manufacturers of Clamp Alternatives for Pipe Repair, Manufacturers of High Pressure Pipe pin-hole Repair Clamps, Manufacturers of Boltable Split Sleeve pin-hole Repair Clamps, Manufacturers of 2″ Pipe pin-hole Repair Clamps for Steel, Manufacturers of Leak pin-hole Repair Clamps, Manufacturers of a516 gr. 70 Leak pin-hole Repair Clamps, manufacturers of heavy duty Leak pin-hole Repair Clamps, Manufacturers of carbon steel Leak pin-hole Repair Clamps, Manufacturers of piping Leak pin-hole Repair Clamps, Manufacturers of oil pipline Leak pin-hole Repair Clamps, Manufacturers of gas pipe line Leak pin-hole Repair Clamps, Manufacturers of emergency Leak pin-hole Repair Clamps, Manufacturers of offshore Leak pin-hole Repair Clamps, , Manufacturers of onshore Leak pin-hole Repair Clamps, Split Clamp, Sleeves & Fittings.

Key Features

- All pipe range sizes 2” upwards

- Pressure range: up to 153 Bar (900lbs)

- Maximum pin-hole size up to 12mm

- No preparation required

- Can be fitted onto live leak

- Simple to install

- Xylan coating provides excellent corrosion resistance

Material & Standard

STANDARD : API | ASTM | DIN | EN | AS PER CLIENT DRAWING

MATERIAL GRADE :

- API 5L PSL 1 & PSL 2 (Grade B, X46, X52, X56. X60, X65)

- ASTM A53 Grade B / ASTM A106 Grade B

- ASTM A333 Grade 6

- ASTM A516 Grade 60, Grade 65, Grade 70

- ASTM A671 CC60, CC65, CC70

- ASTM A335 P5, P9, P11, P22, P91

- ASTM A691 1-1/4CR, 2-1/4CR, 5CR, 9CR, 91

- Stainless steel TP316, TP 316L, TP304L

We Supply to :

- ASIA – India, Japan, Thailand, Singapore, Sri lanka, Bangladesh, South Korea, Indonesia, Philippines, Vietnam, Kazakhstan, Azerbaijan, Turkmenistan.

- Middle East – Kuwait, Dubai, Saudi Arabia, Qatar, Oman, Bahrain, Jordan, Turkey, Iraq, Yemen, Syria, Azerbaijan, United Arab Emirates, Israel.

- Western Europe – Germany, France, Netherlands, Belgium, Austria, Switzerland, Luxembourg, Monaco, Liechtenstein

- Eastern Europe – Russia, Ukraine, Poland, Romania, Czechia, Hungary,Belarus, Bulgaria, Slovakia, Moldova

- Northern Europe – United Kingdom, Sweden, Denmark, Finland, Norway, Ireland, Lithuania, Latvia, Estonia, Iceland, Isle of Man, Faeroe Islands

- Southern Europe – Italy, Spain, Greece, Portugal, Serbia, Croatia, Bosnia and Herzegovina, Albania, North Macedonia, Slovenia, Montenegro, Malta, Andorra, Gibraltar, San Marino, Holy See

- South America – Argentina, Chile, Brazil, Colombia, Paraguay

- Western Africa – Nigeria, Ghana, Côte dIvoire, Niger,Burkina Faso, Mali, Senegal, Guinea, Benin, Togo, Sierra Leone, Liberia, Mauritania, Gambia, Guinea-Bissau, Cabo Verde, Saint Helena

- Northern Africa – Egypt, Sudan, Algeria, Morocco, Tunisia, Libya, Western Sahara

- Southern Africa – South Africa, Namibia, Botswana,Lesotho, Swaziland

- Eastern Africa – Ethiopia, Tanzania, Kenya, Uganda,Mozambique, Madagascar, Malawi, Zambia, Zimbabwe, South Sudan, Rwanda, Burundi, Somalia, Eritrea, Mauritius, Djibouti, Réunion, Comoros, Mayotte, Seychelles