Adi-Sleeve

A (Adi-Sleeve) pipe insert sleeve, also known as a pipe sleeve, is a protective barrier that shields pipes from corrosion, abrasion, and other threats:

Pipe insert sleeves protect the integrity of pipes by creating a barrier between the pipe’s internal coating and the substances being transported. They can also isolate damaged areas of a pipe from the heat of welding.

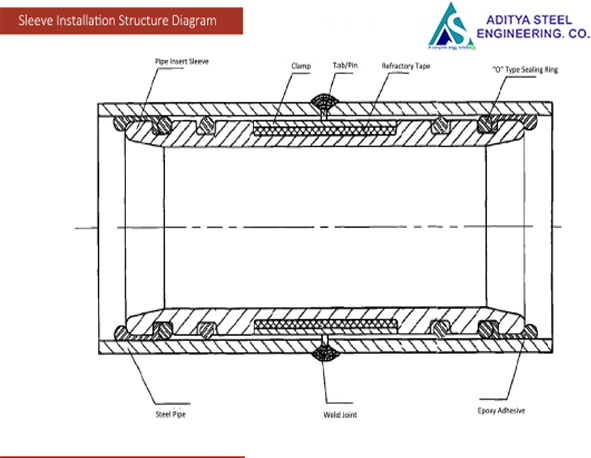

By creating a continuous internal coating transmission at the joint welding section, Aditya’s pipe insert sleeve is a pipe fitting specifically made to shield the welded joint area of piping from corrosive process fluids. Both onshore and offshore pipeline installations can use this product for field jointing, and it can be made in a variety of sizes, grades, materials, and piping system configurations. Both liquid and powder pipe coatings can be used with the sleeve.

The pipe insert sleeve’s design aims to extend the pipeline’s service life by offering a consistent internal coating for internally coated pipes while taking into account the cleaning and operation of the pipeline following installation.

The pipe insert sleeve offers satisfactory protection for the pipeline internal cutback area when the right coating is applied that is appropriate for operating under the particular transporting medium conditions of each project, high temperature isolation treatment for pipe welding, and the use of high temperature and corrosive resisting sealing rings and mastic epoxy.

- Ad-Sleeve Materials

Pipe insert sleeves are typically made from polymers like polypropylene or polyethylene.

- Ad-Sleeve Coatings

Pipe insert sleeves can be coated internally and externally with liquid or powder coatings. The coating depends on the material flowing through the pipeline.

- Ad-Sleeve Applications

Pipe insert sleeves are used in a variety of industries and applications, including water pipelines, oil and gas pipelines, refineries, desalination plants, and more.

- Ad-Sleeve InstallationPipe insert sleeves are easy to install and don’t require special equipment.

The following are the essential qualities of a certain coating system.

Protective coating must remain defect free within reasonable limits over time, especially in places with considerable temperature changes.

Coating must be tolerant to handling during construction & field bending and in service deterioration.

Following are the essential properties of coating system:

- Penetration Resistance

- Resistance to cathodic disbondment

- Stability at elevated temperature

- Resistance to soil stress

- Resistance to water absorption

- Chemical resistance (Acids & alkali)

- Volume resistivity

- Flexibility to bending

- Hardness (abrasion resistance)

- Maintenance and refurbishment frequency

- HSE consideration

- Resistance to damages during handling

Internal Pipe Sleeve Benifits :

Flexibility : Thin-gauge assembly adjusts to pipe shape for easy insertion & consistent seal quality.

Sealing : Bore seals accommodate pipe ID tolerances and seal at any pipeline pressure.

Weld Quality : Flexibility allows for a better fit, easier root pass, and more consistent weld quality.

Heat Resistance : Wider sleeve & thicker insulation reduces heat impact & does not slow down welding.

Large Diameters : Accommodates out of round pipe

Automatic Welding : Compatible with internal lineup clamps & automatic welding

Internal Pipe Sleeve advantages for online pipe lines.

- Internal pipe sleeve applicable to a wide range of pipeline systems, both onshore and offshore.

- Internal Pipe Sleeve can be made to fit the line pipe internal area.

- The greath weld joint can be 100% X-Rayed completely.

- Any liquid coating or powder coating can be coat to internal pipe sleeves

- Internal pipe sleeve are made to fit the cut-back portion of the internal coated pipe.

- Internal pipe sleeve have the advantage of being simple to manufacture and can be manufactured alongside the pipeline where they will be installed, saving a significant amount of time when compared to complex robotics technology, where the work can only begin after the welding process of the pipe is completed.

- Heat generated within the pipe during the welding operation will burn back the internal plastic layer roughly 1-2 inches from the welding seam. The sleeves and fittings are intended to isolate the coating burn-back and preserve the steel substrate.

Internal Pipe Sleeve production Material Grade.

Aditay Steel Engineering Co. is a renowned producer, suppliers and exporters of internal pipe sleeves in the special Indian, European, Japanese, and Korean raw material pipes grades as API 5L LINE PIPES PSL 1 & PSL 2, SOUR SERVICE NACE MR0175, HIC-SSC Tested, and engineers for oil and gas field pipe line weld joints protection suppliers. API 5L X46, X52, X60, X65, X70, and X80 grade In Vasai, Thane, and Mumbai, India.

ASE Internal pipe sleeves must adhere to the following ASTM standards: ASTM A53, ASTM A106, ASTM A333, ASTM A36, ASTM A516 CL 60, CL 65, and CL 70; ASTM A671, ASTM A672 pipe internal insert sleeves; ASTM A691, ASTM A312 pipe internal insert sleeves; and ASTM A358 internal pipe insert sleeves.

OUR MAIN MANUFACTURING CLAMP AND EXPORT COUNTRIES AS FOLLOWS :

- ASIA – India, Japan, Thailand, Singapore, Sri lanka, Bangladesh, South Korea, Indonesia, Philippines, Vietnam, Kazakhstan, Azerbaijan, Turkmenistan.

- Middle East – Kuwait, Dubai, Saudi Arabia, Qatar, Oman, Bahrain, Jordan, Turkey, Iraq, Yemen, Syria, Azerbaijan, United Arab Emirates, Israel.

- Western Europe – Germany, France, Netherlands, Belgium, Austria, Switzerland, Luxembourg, Monaco, Liechtenstein

- Eastern Europe – Russia, Ukraine, Poland, Romania, Czechia, Hungary,Belarus, Bulgaria, Slovakia, Moldova

- Northern Europe – United Kingdom, Sweden, Denmark, Finland, Norway, Ireland, Lithuania, Latvia, Estonia, Iceland, Isle of Man, Faeroe Islands

- Southern Europe – Italy, Spain, Greece, Portugal, Serbia, Croatia, Bosnia and Herzegovina, Albania, North Macedonia, Slovenia, Montenegro, Malta, Andorra, Gibraltar, San Marino, Holy See

- South America – Argentina, Chile, Brazil, Colombia, Paraguay

- Western Africa – Nigeria, Ghana, Côte dIvoire, Niger,Burkina Faso, Mali, Senegal, Guinea, Benin, Togo, Sierra Leone, Liberia, Mauritania, Gambia, Guinea-Bissau, Cabo Verde, Saint Helena

- Northern Africa – Egypt, Sudan, Algeria, Morocco, Tunisia, Libya, Western Sahara

- Southern Africa – South Africa, Namibia, Botswana, Lesotho, Swaziland

- Eastern Africa – Ethiopia, Tanzania, Kenya, Uganda, Mozambique, Madagascar, Malawi, Zambia, Zimbabwe, South Sudan, Rwanda, Burundi, Somalia, Eritrea, Mauritius, Djibouti, Réunion, Comoros, Mayotte, Seychelles.