Aditya Steel Engineering co. is India’s top manufacturer of pipe sleeve known as internal weld pipe sleeve, weld joint pipe sleeve, greath weld protaction weld sleeve, pipe insert sleeve, pipe internally insert sleeve, anti-corrosion sleeve in india

Engineers at Aditya Steel Engg. Co. have thoroughly researched the issue of preventing internal corrosion in pipelines with welded joints. They can assist you in exploring the various lining and joint solution options accessible.

Aditya Steel Engg. Co. is one of the firms producing carbon steel pipe sleeves with the fastest growth rate. We offer these coverings in conventional and customised forms at affordable prices, depending on our clients’ demands. Aditya Steel & Engg. Co. manufactures these pipe insert sleeves in a range of sizes, forms, and specifications that meet international requirements. This raw material is supplied by a reputable exporter.

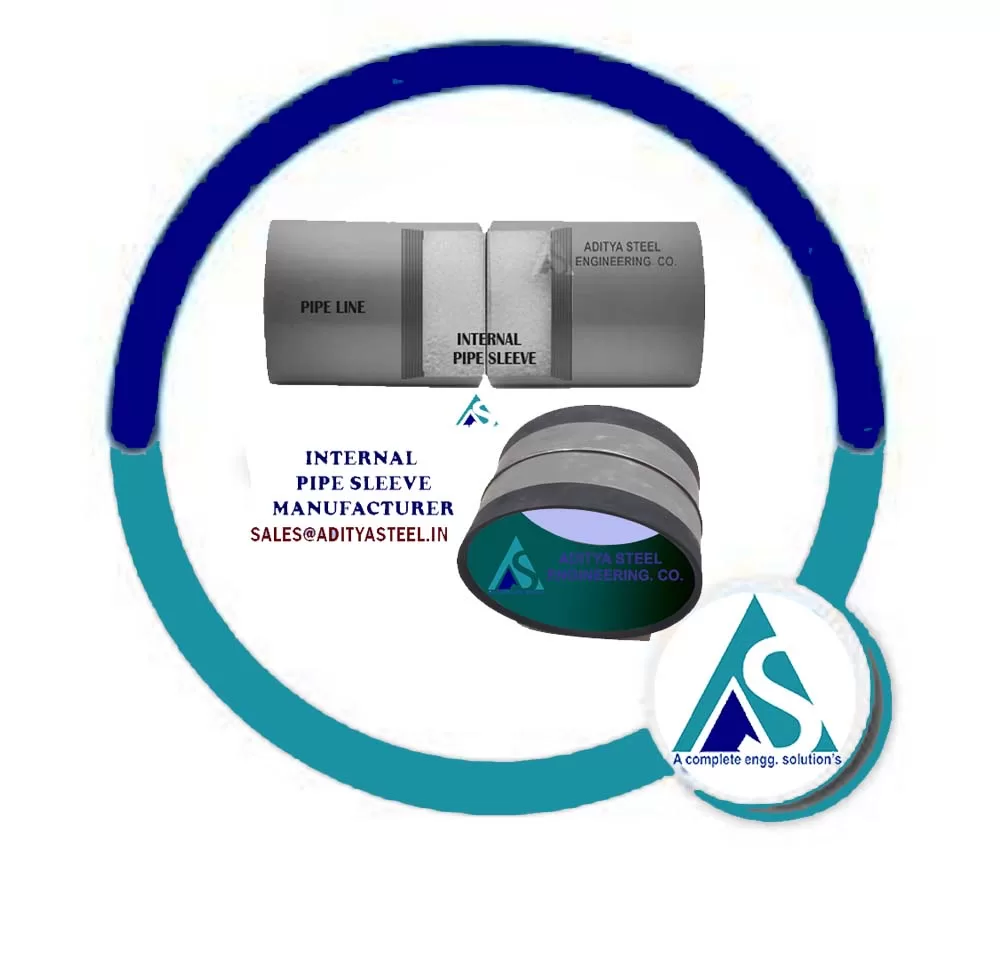

Internal Weld Pipe Sleeve

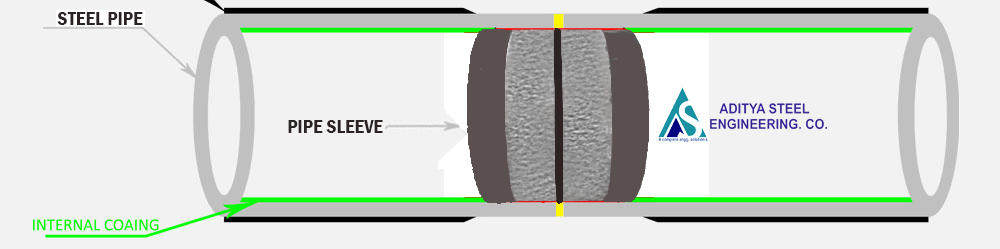

The (Pipe Insert Sleeve) internal insert sleeve is a pipe sleeve designed to shield the welded joint region of piping from corrosive process fluids by establishing a continuous internal coating transmission at the joint welding section. This product may be created in a broad range of sizes, grades, materials, and piping system configurations, and it can be utilised in both onshore and offshore pipeline construction field jointing. The cover is compatible with liquid or powder pipe coatings.

The pipe insert sleeve manufactured by ASEC usually has an outer diameter of 2 inches to 48 inches and fits internally coated pipelines. (60.3mm-1219mm). It is advised to apply internal field joint coating using ASEC internal field joint coating robot for pipes larger than 12 inches.

The design purpose of the pipe insert sleeve (pipe sleeve) is to provide a uniform internal coating for internally coated pipelines while taking into consideration the maintenance and cleaning chores that must be performed on the pipeline after installation. This will extend the pipeline’s service life.

The pipeline internal greath weld area is satisfactorily protected by the pipe insert sleeve thanks to the application of the proper coating that is appropriate for working under the unique transporting medium conditions of each project, high temperature isolation treatment for pipe welding, and the use of high temperature and corrosive resisting sealing rings and mastic epoxy.

Advantages of Pipe Insert Sleeve for Internal Field Joint Coating.

• Easy installation

• Increasing pipeline service life

• Increasing flow efficiency

• Reducing internal corrosion

• Providing coherent pipeline internal protection

• Reducing pipe wall thickness requirements

• Diminishing or eliminating pipeline leaks

Aditya Steel Pipe Insert Sleeves Material Grade

API 5L LINE PIPES PSL 1 & PSL 2, SOUR SERVICE NACE MR0175, Grade x46, x52, x60, x65, x70, x80 | ASTM A53 | ASTM A106 | ASTM A333 | ASTM A36 | ASTM A516 CL 60, CL 65, CL 70 | ASTM A671 | ASTM A672 | ASTM A691 | ASTM A312 | ASTM A358 etc.

OUR MAIN MANUFACTURER AND EXPORT COUNTRIES.

- ASIA – India,Thailand, Singapore, Sri lanka, Bangladesh, India, Indonesia, Viatnam, China, South Korea, Hong Kong, Japan.

- Middle East – Kuwait, Dubai, Saudi Arabia, Qatar, Oman, Bahrain, Jordan, Iraq, Iran, Lebanon, United Arab Emirates, Algeria, Tunisia.

- Europe – United Kingdom, Italy, Belgium, France, Croatia, Spain, Germany, Poland, Finland, Grees,

- South America – Argentina, Chile, Brazil, Colombia, Paraguay, Colombia, Ecuador/Ikwayur/Ekuatur, Falkland Islands, Guyane, Guyana, Paraguay/Paraguái, Perú/Piruw/Piruw, South Georgia and the South Sandwich Islands, Suriname, Uruguay/Uruguai, Venezuela

- Africa – South Africa, Eastern Africa, Northern Africa, Ethiopia, Egypt, DR Congo, Tanzania, South Africa, Kenya, Uganda, Algeria, Sudan, Morocco, Angola, Mozambique, Ghana