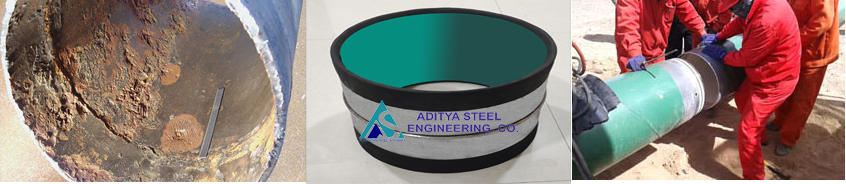

Manufacturer and Exporters of Pipe Sleeve’s

The purpose of a internal pipe insert sleeve (Pipe sleeve) is to create a continuous internal coating transmission at the joint welding section of piping to protect the welded joint area from corrosive process fluids. This product can be manufactured to be a wide variety of sizes, grades, materials, or piping system configurations, and it can be used in field jointing of both onshore and offshore pipeline installation. The cover works with pipe coatings made of liquid or powder materials.

Pipe Sleeve for pipe internal insert.

Advantages of Pipe Insert Sleeve for Internal Field Joint Coating.

- Easy assembly.

- Increased flow efficiency

- Decreased internal corrosion

- Coherent pipeline internal protection

- Decreased pipe wall thickness requirements

- and decreased or eliminated pipeline leaks are all benefits.

The pipe insert sleeve’s design goal is to provide a consistent internal coating for internally coated pipelines while taking into account the maintenance and cleaning tasks that must be done on the pipeline after installation. This will prolong the service life of the pipeline.

The pipeline internal cutback area is satisfactorily protected by the pipe insert sleeve thanks to the application of the proper coating that is appropriate for working under the unique transporting medium conditions of each project, high temperature isolation treatment for pipe welding, and the use of high temperature and corrosive resisting sealing rings and mastic epoxy.

The pipe insert sleeve produced by ASEC fits internally coated pipelines with an outer diameter that usually varies from 2 inches to 48 inches. (60.3mm-1219mm). It is advised to apply internal field joint coating using ASE internal field joint coating robot for pipes larger than 12 inches.

Pipe sleeve coating facility

- Internal Novalac-Epoxy Powder Coatings Servicing in Sour, High Temperature.

- External FBE Coatings.

- Internal FBE Coatings.

- Solvent-free Phenolic Epoxy for FBE Coating Repair.

- illing and Sealing Mastic.

- Solvent Free Novolac Epoxy Liquid Coatings.

- Liquid Phenolic Primer for FBE Coatings.

- Food grade coating

The pipes sleeves adhere to the following standards:

ASEC equipped to offer a variety of coatings to satisfy varying standards and customers’ needs, including HDPE lined, insulation coating, bitumen coating, liquid epoxy coating, and internal and/or external coating of FBE, Piping Fabrication.

- Related Standard & Specification: API, DNV, ISO, DEP, EN, ASTM, DIN, BS, JIS.

- Related Grade: API 5L -X70, ASTM A252 GR1- GR3, ASTM A572 GR 50, AS1163 Series, A-X80, L190-L555.

- Available Approved Marine: ABS/BV/LR/DNV/GL/KR, EN10204 3.2 MTC.

- Special Service: Sour Service , NACE MR0175/ISO15156

Top Countries We Export.

- ASIA – India,Thailand, Singapore, Sri lanka, Bangladesh, India, Indonesia, Viatnam, China, South Korea, Hong Kong, Japan.

- Middle East – Kuwait, Dubai, Saudi Arabia, Qatar, Oman, Bahrain, Jordan, Iraq, Iran, Lebanon, United Arab Emirates, Algeria, Tunisia.

- Europe – United Kingdom, Italy, Belgium, France, Croatia, Spain, Germany, Poland, Finland, Grees,

- South America – Argentina, Chile, Brazil, Colombia, Paraguay, Colombia, Ecuador/Ikwayur/Ekuatur, Falkland Islands, Guyane, Guyana, Paraguay/Paraguái, Perú/Piruw/Piruw, South Georgia and the South Sandwich Islands, Suriname, Uruguay/Uruguai, Venezuela

- Africa – South Africa, Eastern Africa, Northern Africa, Ethiopia, Egypt, DR Congo, Tanzania, South Africa, Kenya, Uganda, Algeria, Sudan, Morocco, Angola, Mozambique, Ghana.